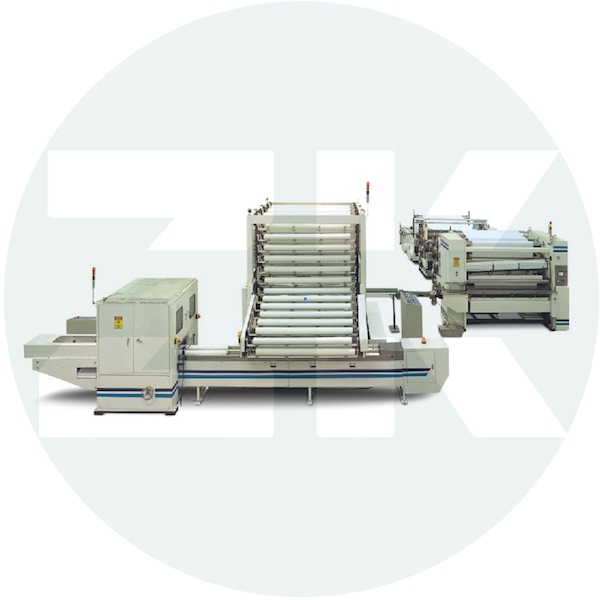

ZM-TK-450 Fully-Automatic Non-stop with Lamination |

TK450 Toilet Paper and Kitchen Towel Production Line - Installed at 2020 in İzmit |

TK450 Toilet Paper and Kitchen Towel Production Line |

|

|

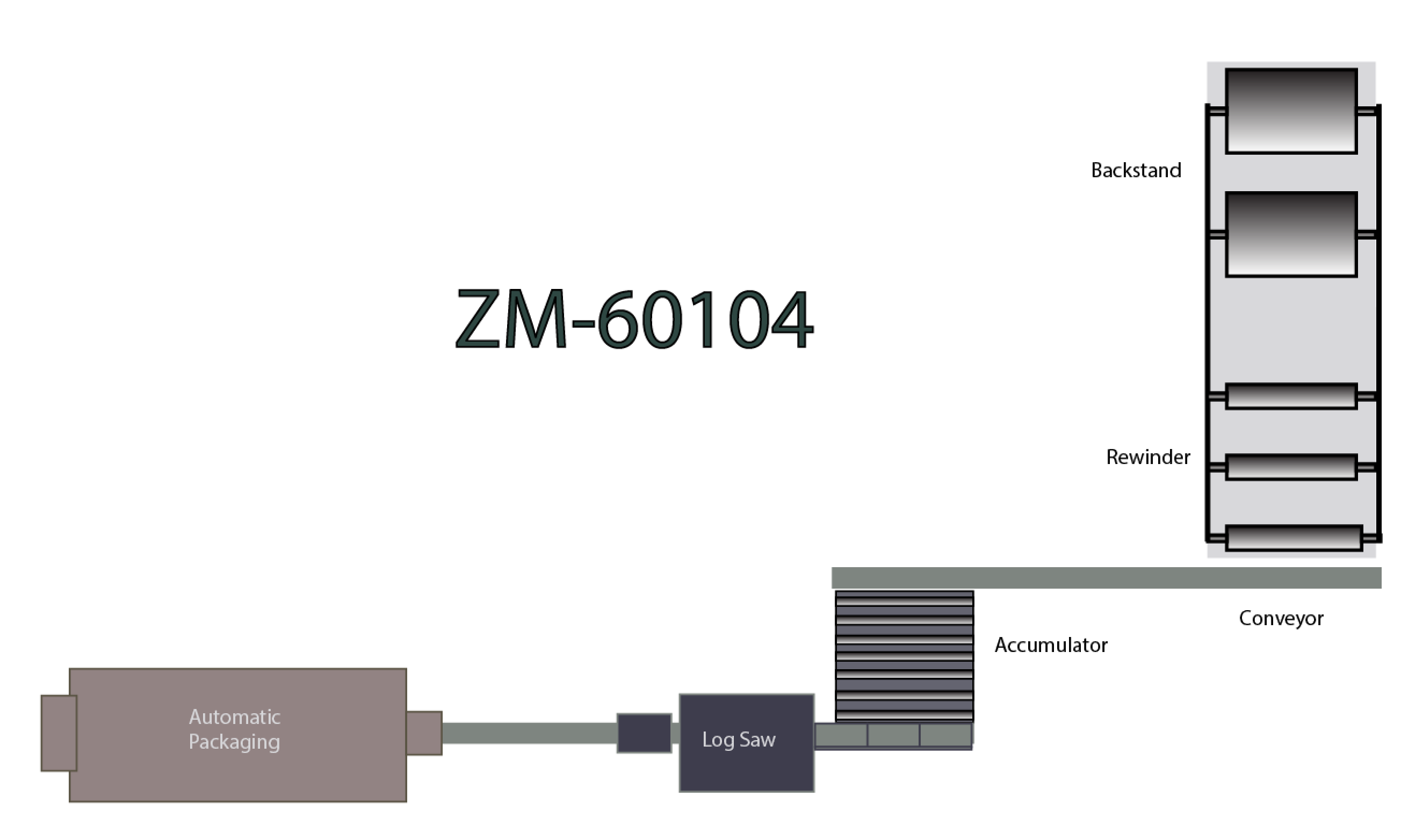

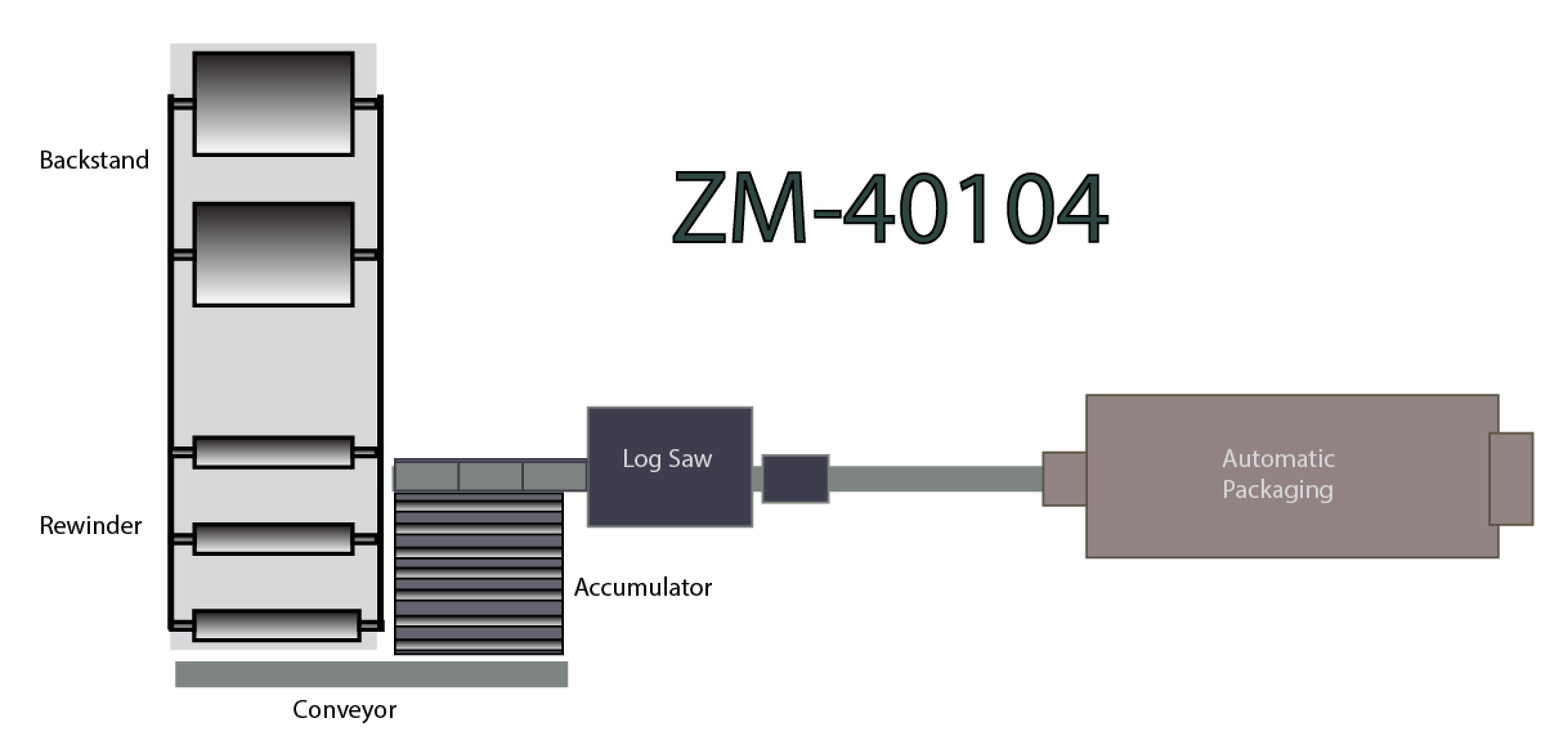

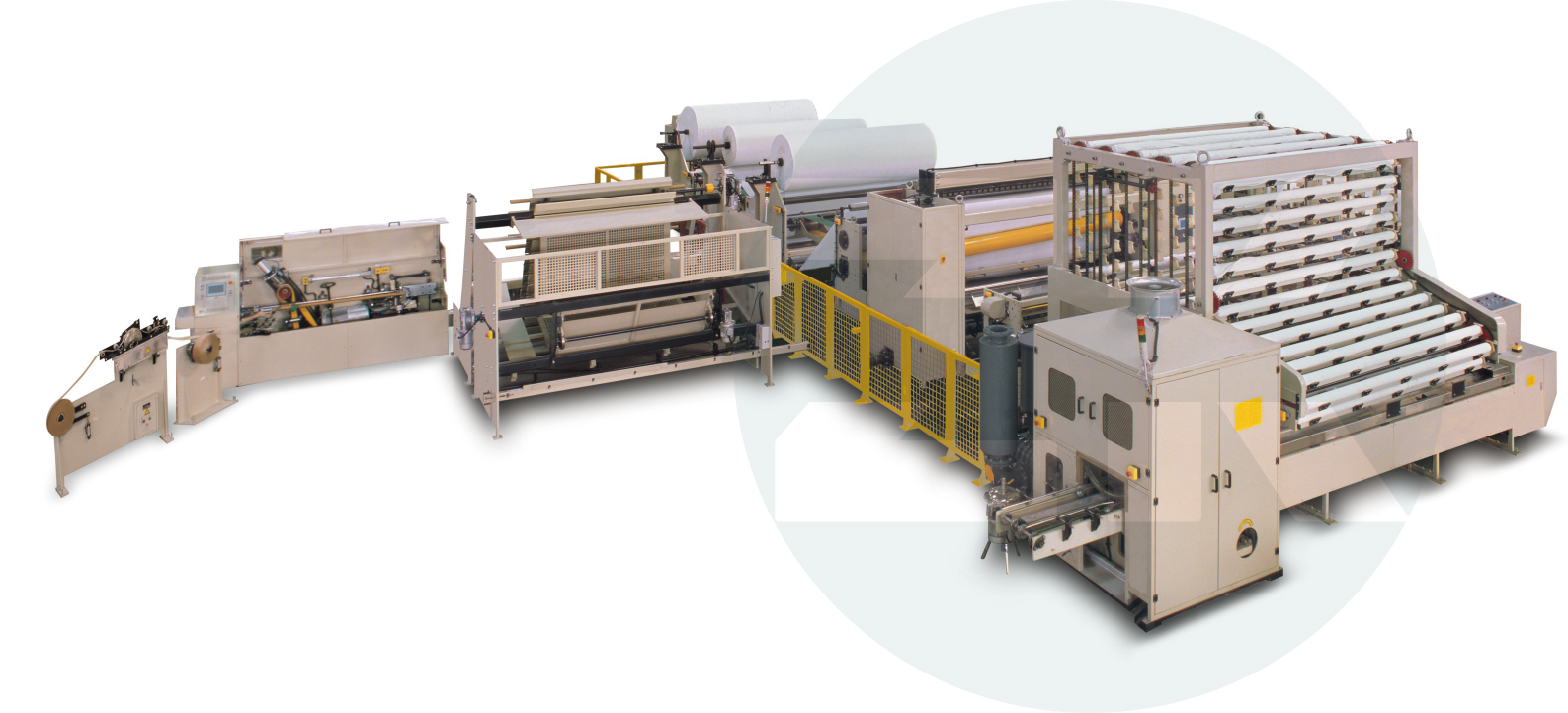

ZM-TK-450 Full Line of Toilet Paper Production |

|

|

Fully Automatic Non-Stop Toilet Paper and Kitchen Towel Machine |

ZM-TK-450 Fully Automatic Toilet Paper and Kitchen Towel Machine

ZM-TK-450

Fully Automatic Toilet Paper and Kitchen Towel Machine

ZM-TK-450, adopts global advanced Programming Logic Control (PLC) technology and inverter controls machine speed. It is equipped with a servo winding unit and a touch screen operation panel. This machine has easy-operation, low-noise, high-quality features and it is the top choice for toilet roll or kitchen towel producers with its consecutive non-stop operation.

1. Non-stop type machine – it continuously rewinds.

2. Each unit is driven by an independent motor (servo motor).

3. Simple structure decreases the failure rate.

4. Servo motor controls machine head and brake.

5. High-precision NC machine large diameter blade shaft, Siemens SIMOTION system and automatic blades axial slid function guarantee precise and clear perforation, and the rolls have finest tightness and diameter.

6. Perforation size could be set on the HMI.

7. Patented technology: uses the constant-vacuum system to start rewinding coreless roll, faster and with less wrinkles.

8. * Optionally, the double-perforated blade can easily and quickly move from the perforation size of the small-diameter toilet paper, to the large-sized kitchen towel.

|

Model |

ZM-TK-450 3600/2900/2500 |

ZM-TK-350 3600/2900/2500 |

|---|---|---|

|

Design Speed |

0-450 m/min |

0-350 m/min |

|

Guarantee Operation Speed |

With core 0-400 m/min |

With core 0-300 m/min |

|

* Max. Width of Raw Paper (mm) |

3600/2850/2400 (Other sizes should be specified.) |

|

|

* Max. Outer Diameter of Raw Paper |

1500 mm (Customized sizes can be done. Max. Diameter can be 2500 mm) |

|

|

Parameter Setting |

HMI Touch Screen |

|

|

Machine Control System |

Full SERVO |

|

|

Program Control |

PLC + Full SERVO system |

|

|

* Embossing Roller |

For laminated toilet paper/kitchen towel: 4 set laser(engraved) point-to-point or nested pneumatic embosser |

|

|

Counter Embossing Roller |

Rubber |

|

|

* Outer Diameter of Finished Product (mm) |

65-140, please specify other sizes |

|

|

Diameter Control of Finished Product |

Electronic (Servo) |

|

|

Counting of Finished Product Sheets |

Electronic (Servo) |

|

|

Control of Product Finish |

According to length or the diameter of the toilet roll |

|

|

Perforation Blade |

6 helix perforating blades (made in Germany), driven by independent motor |

4 helix perforating blades (made in Germany), driven by independent motor |

|

Perforation Length |

6 blades 80-150mm |

|

|

* Double Perforation Blade Shaft |

Optional |

|

|

Web Feeding Protection |

Automatic web thickness monitor |

|

|

* Outer Diameter of Finished Product Core (mm) |

35-50 |

|

|

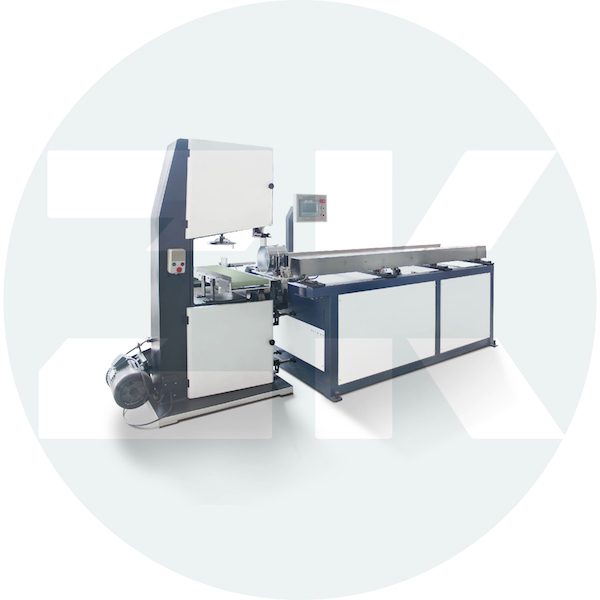

Core Transfer |

This machine has an automatic high-speed core production line and this line transfers cores to the machine automatically. |

|

|

Core Gluing |

Less than 2 pitches wrinkle pitches per roll |

|

|

Mechanic Driving |

Timing belt system |

|

* Back-stand |

1-4 (1-4 plies, with shaft or shaft less) |

|

|

Web Edge Control |

Controlled by PLC, tracked with sensor |

|

|

Edge Embossing |

Pneumatic |

|

Typical Tail Sealer |

40 log/min |

|

|

Clean Cut SERVO System |

This machine can break off the last sheet of toilet roll from the perforated point with adopted clean cut servo system which reduces wastage of tissue paper explicitly compared to other machines. |

|

|

* Lamination Unit |

Gluing for nested or point to point embossing pattern.(Need to be specified when ordered) |

|

|

* Decorative Gluing System |

The patterns show the pattern on the embossing cylinder. |

|

|

* Coreless Production Function |

Available |

|

|

* Printing |

1-4 color (should be specified when ordering) |

|

* It shows the specifications that are optional or should be specified while ordering.